Efficient. Reliable. Transparent. The Velvety way of manufacturing.

We make no compromises in production. In our IFS-HPC-compliant in-house manufacturing facility, every product is made exactly to specification – safely, on time, and with consistently high quality.

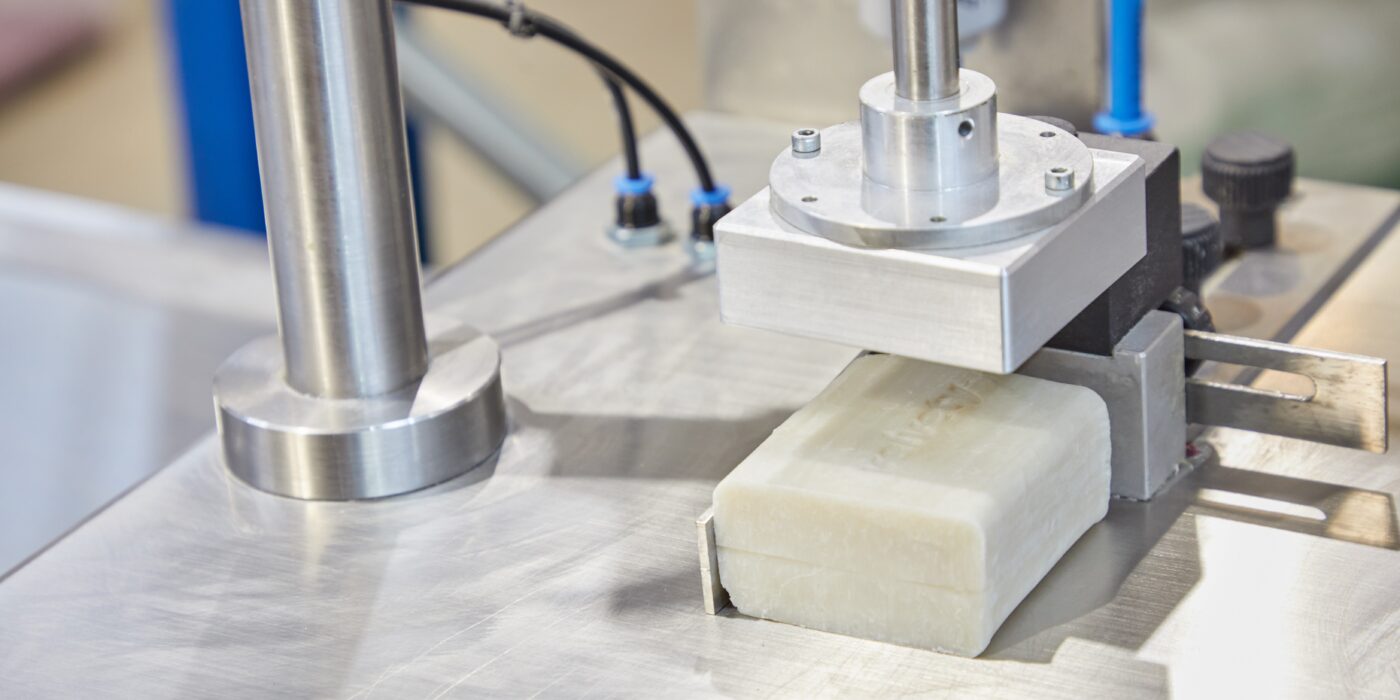

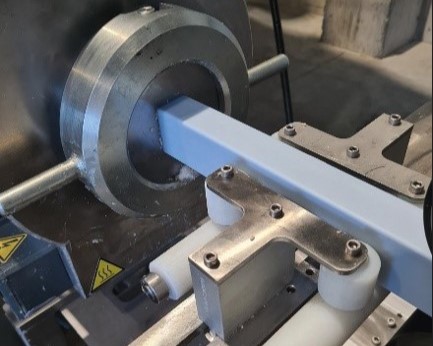

Whether poured, pressed, extruded, filled, or handmade – we select the ideal manufacturing process for your private-label cosmetics, precisely tailored to the product format, texture, and application.